A common characteristic of most mechanical and chemical systems is the need to transfer heat from one fluid (liquid or gas) to another, and most systems use heat exchangers to accomplish this task. In a heat exchanger, the two fluids do not make direct contact. Instead, heat passes from the hotter fluid to the metal isolating the fluids and then to the cooler fluid.

Common applications of heat exchangers include heating, ventilation, and air conditioning (HVAC) systems; preheaters or coolers in fluid systems; radiators on internal combustion engines; and boilers, evaporators, and condensers used with fluids like oils, wastewater, hydrocarbons, biogases, etc. in industries such as oil and gas refining and power generation.

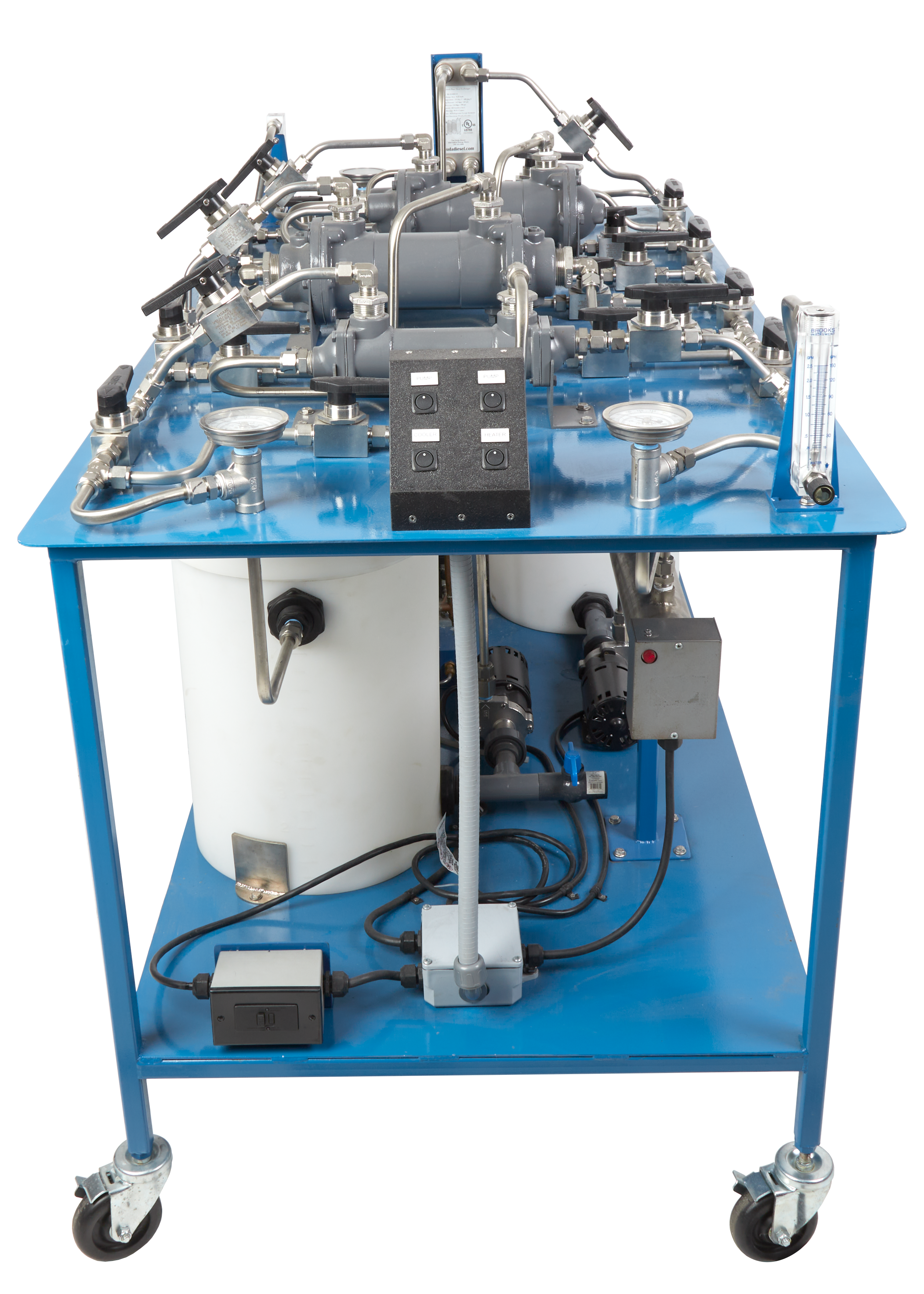

Bayport Technical's Heat Transfer Trainer (110-HTDU) provides comprehensive heat transfer training for the process industry, including valuable hands-on experience with four different types of heat exchangers: brazed plate, brass single pass tube and shell, stainless steel single pass tube and shell, and four pass tube and shell.

The Heat Transfer Trainer features a wide variety of real industrial components, including: two pumps for hot and cold fluid, manifolded with valving; a water heater with storage tank; a refrigerant-type water chiller with storage tank; flow meters and controllers; and digital thermometers.