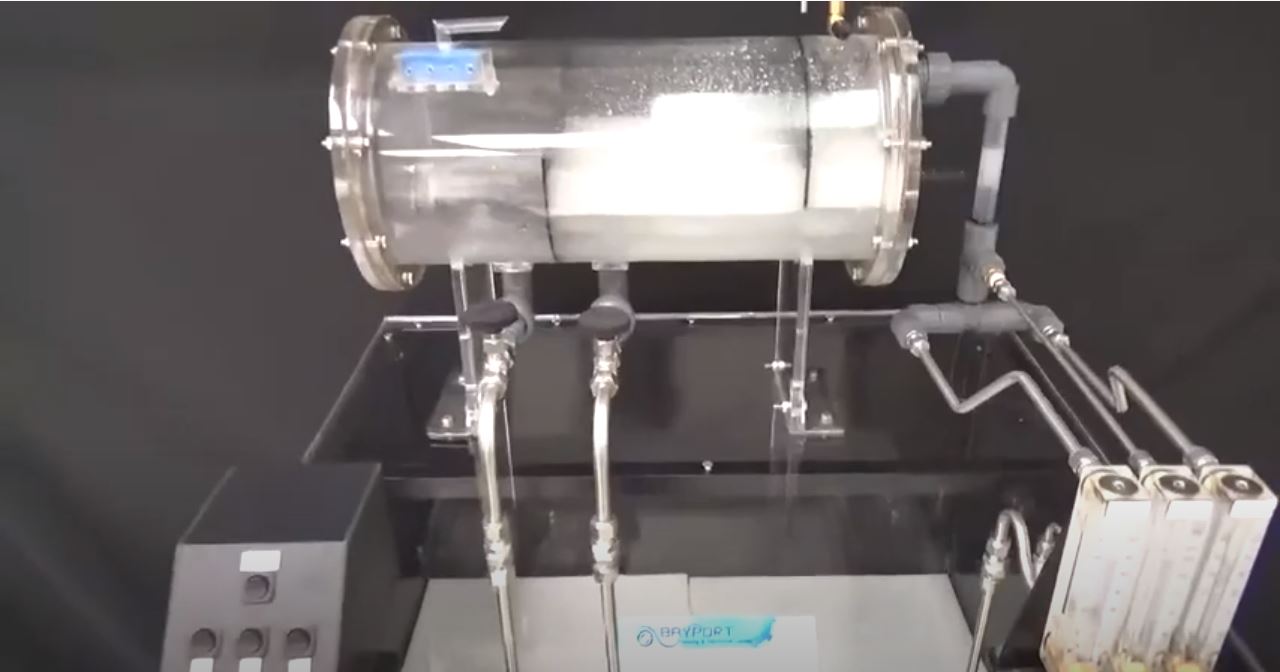

Bayport Technical's 3 Phase Separator Working Demonstrator - Acrylic (142-3PS) simulates the crude oil production process of separating water, oil, and gas before it is shipped to an oil refinery. This hands-on, see-through 3-phase separator training system continuously mixes air, water, and a hydrocarbon-based fluid that allows learners to understand the flow and gravity separation in this essential oil and gas industry application.

This horizontal separator training system is mounted on a metal structure with casters for easy mobility and features two pumps for oil and water, an air compressor, acrylic separation vessels, oil and water storage tanks, and three manual flow meters.

How Does a 3-Phase Separator Work?

The purpose of a 3-phase separator – or free-water knockout (FWKO) – is to extract the oil from the other elements in crude oil like air, sediment, and especially water, which can cause corrosion or blockages due to forming tight emulsions. Crude oil enters an inlet and hits an inlet diverter, which separates the solids from the gasses. The liquid is then collected in the vessel and internal components use gravity to separate the oil from the water. This process requires highly accurate measurement of the gas and oil ratio and control of the liquid flow, making it a prime example of a process control and instrumentation application.