How Does the Gas Lift Process Work?

Over time, the production of every well eventually drops. One cost-effective method commonly used to boost production when this occurs is known as the gas lift process. It’s an artificial lift method that can improve flow and extend the productive life of a well.

The gas lift process involves pumping high-pressure gas into a tube line below the liquid in the well. The injected gas decreases the density of the liquid in the tube line, reducing the pressure needed to push the liquid out of the well to the point that bottomhole pressure is sufficient.

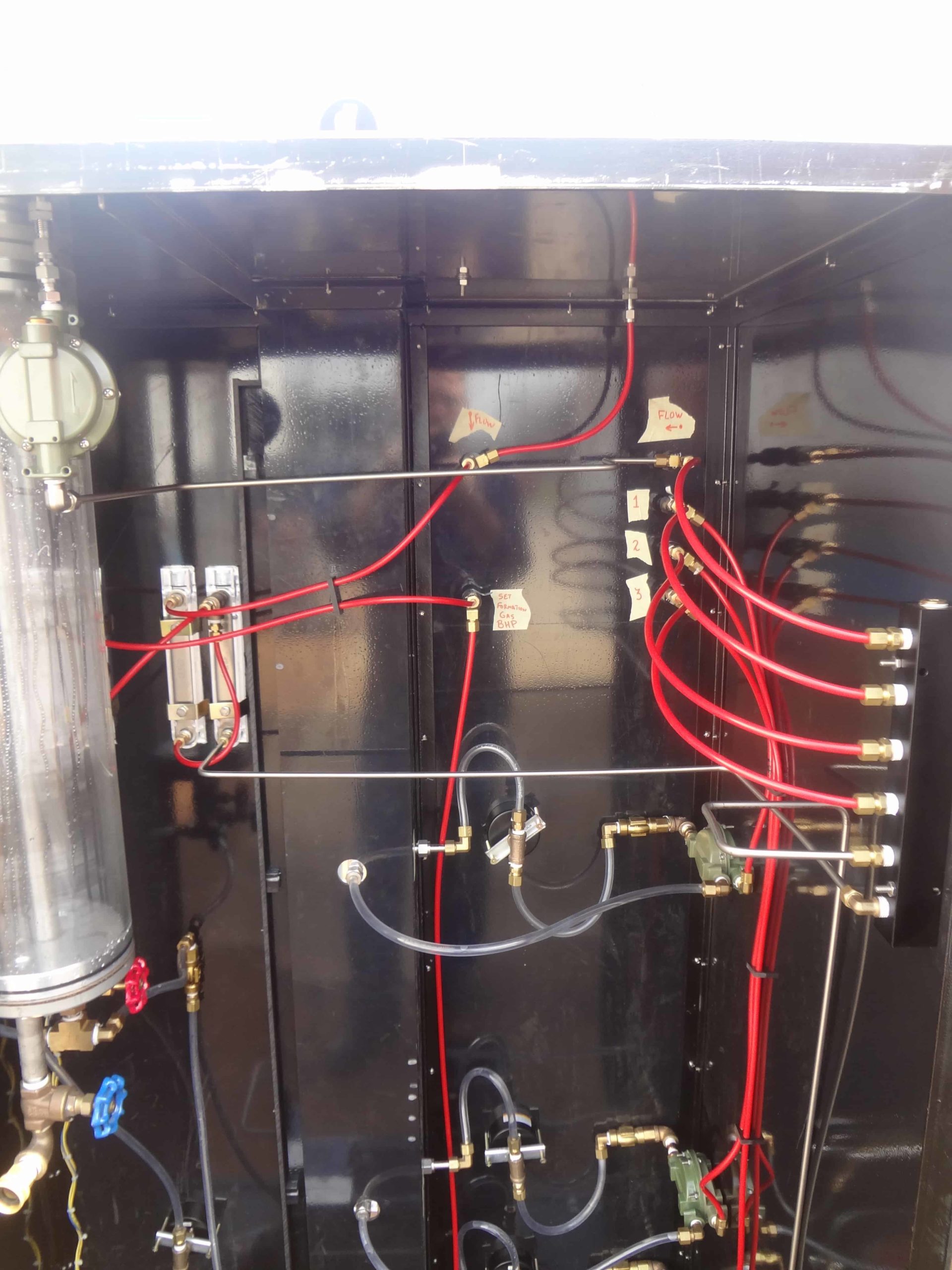

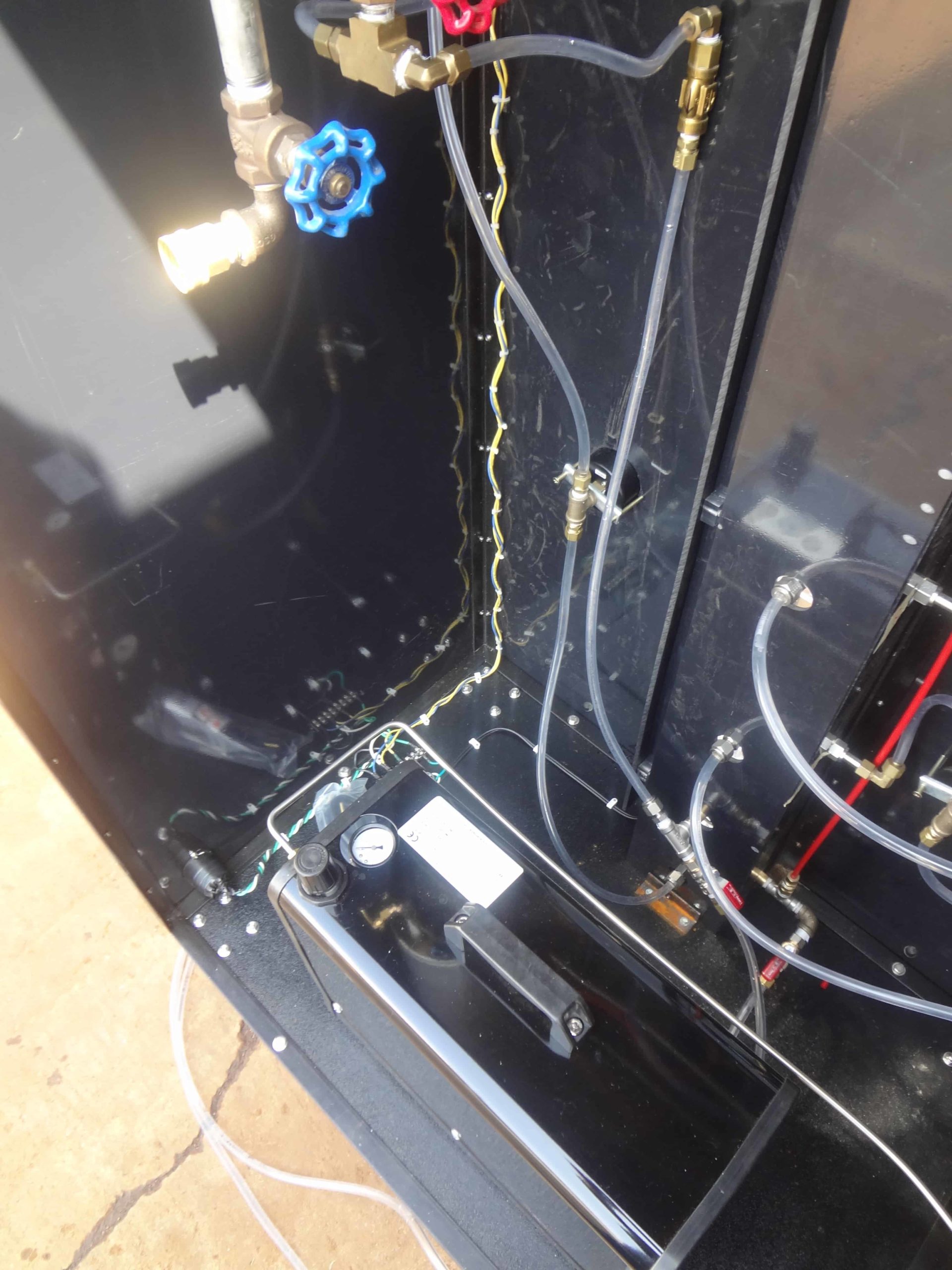

Bayport Technical's Gas Lift Process Trainer (140-GLPT) is designed to illustrate the injection of gas into the production piping of wells with inadequate formation pressure to flow independently. The unit contains multiple regulators, valves, and gauges to allow for broad training opportunities associated with the upstream arena.

The Gas Lift Process Trainer features a wide variety of industry-standard equipment, including: an air compressor; a gas lift valve; regulators, casing, and tubing; pressure gauges; gas and fluid meters; and ID tags.