What Is a Distillation Tower?

A distillation tower (also known as a distillation column) is an essential piece of industrial equipment used to distill liquid mixtures into their component parts (also known as fractions) based upon the differences in their relative boiling points (also known as volatilities).

For example, at atmospheric pressure, water boils at 212°F and ethanol boils at approximately 176°F. If a mixture of water and ethanol is heated to 195°F, the ethanol will boil and change into vapor, which can then be collected and condensed. The water that has been separated out remains a liquid.

Distillation towers typically consist of an enclosed cylindrical structure with several major components, including: trays, plates, and/or packings that aid in component separation; a reboiler to heat the mixture; a condenser to cool and condense vapor; and a reflux drum to hold condensed vapor so liquid can be recycled back to the tower.

How Does a Distillation Tower Work?

The liquid mixture to be distilled (also known as the feed) usually enters the middle of the distillation tower via tray called the feed tray. The area above the feed tray is called the enriching or rectification section, and the area below the feed tray is called the stripping section.

The feed flows down the tower and collects at the bottom in the reboiler, where heat generates vapor. The vapor rises up the tower and is cooled by a condenser when it reaches the top. The condensed liquid (also known as distillate or top product) is stored in the reflux drum.

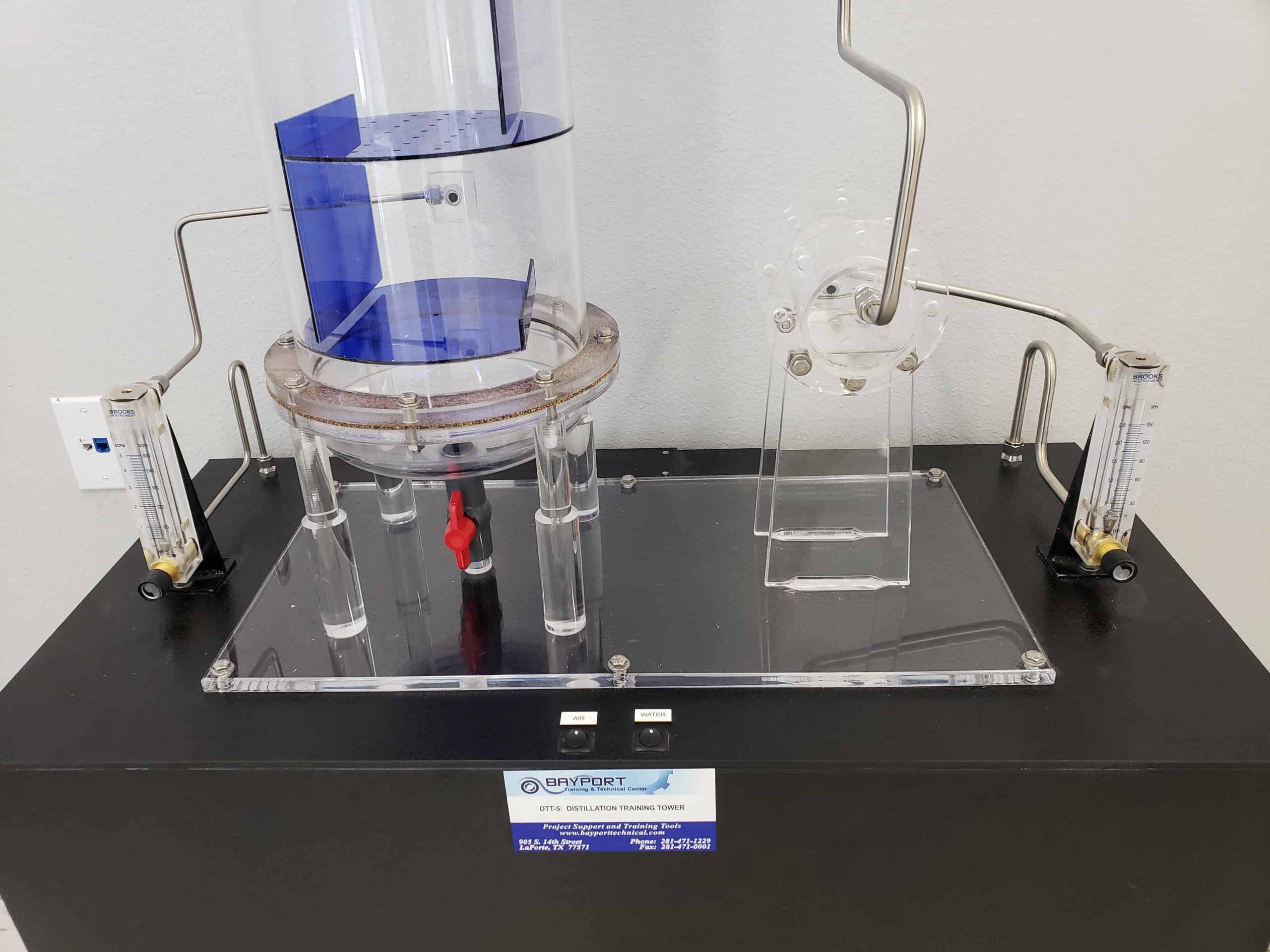

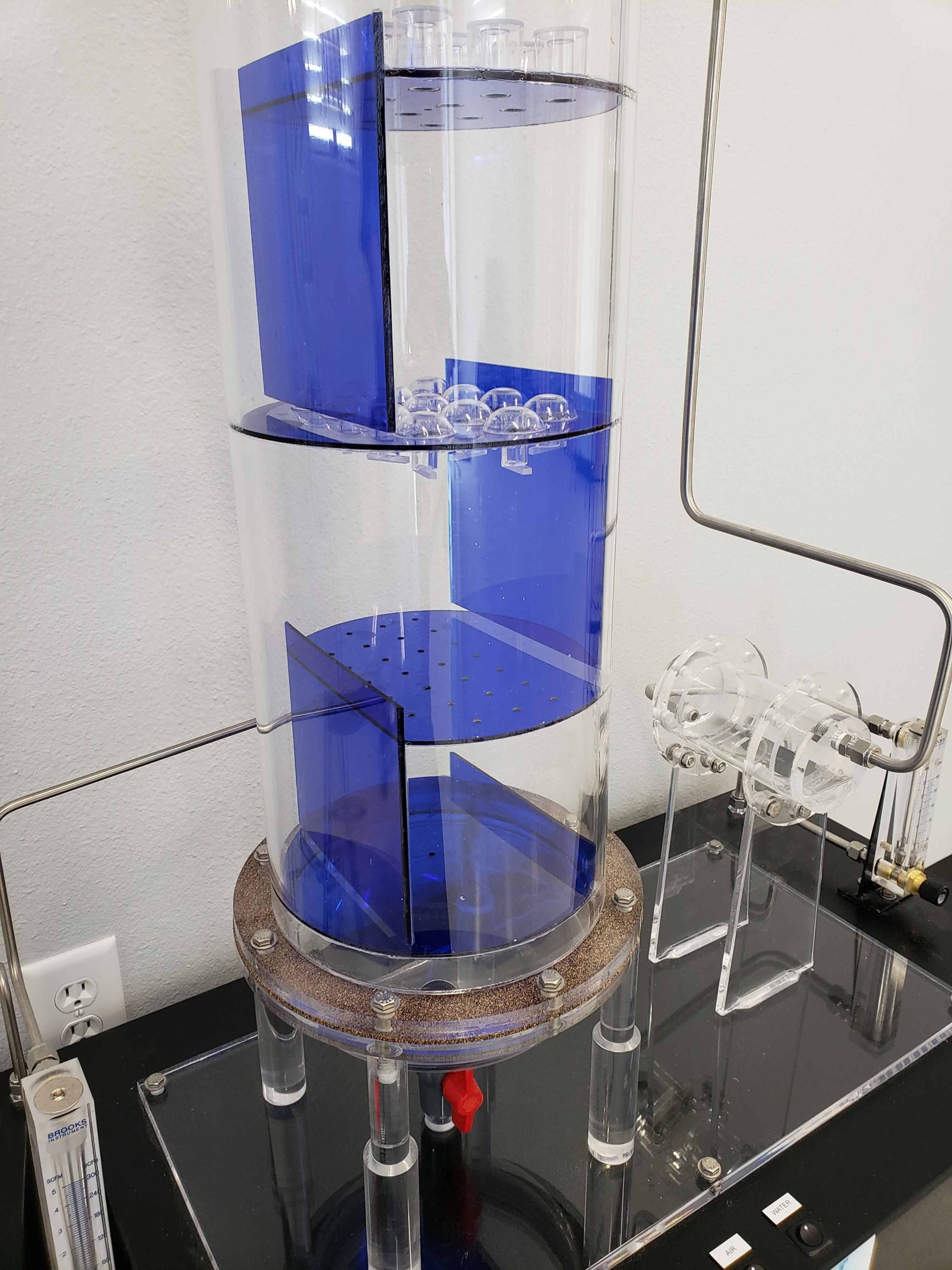

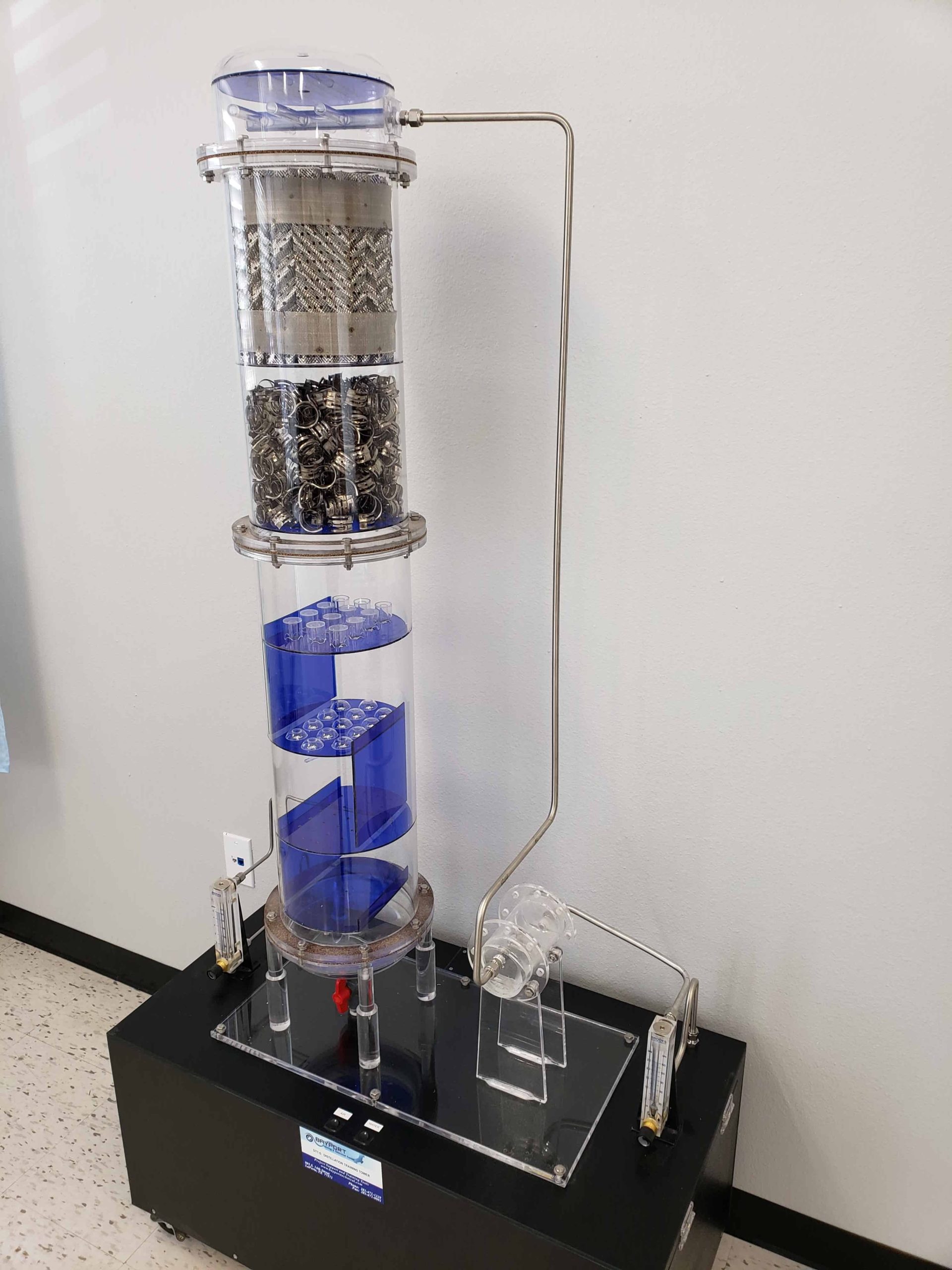

Bayport Technical's Distillation Tower Working Demonstrator - Acrylic, with Reboiler, Rotameters (132-DTT5) is a functioning training aid that demonstrates the operation of a distillation column using water and air. The water simulates the hydrocarbon liquid reflux, and the air simulates the hydrocarbon vapors (gas bubbles).

Water is supplied to the distributor and travels down through the structured packing, across the trays and downward through the downcomers to the water reservoir in the bottom of the stand. Liquid traveling downward comes in contact with the vapors (gas bubbles) traveling upward, thus allowing the cooler liquid to condense any heavy compounds out of the lighter vapor stream. Air travels up through the holes in the trays and is vented out the top to the atmosphere to maintain a flow and relieve pressure.

The Distillation Tower Working Demonstrator - Acrylic, with Reboiler, Rotameters includes the following: base with reservoir, distributor, sieve trays (2) with downcomers, valve tray with downcomer, bubble cap tray with downcomer, structured packing, random packing, centrifugal pump, reboiler, and air compressor.