What Is Process Control?

Process control systems automate the monitoring and adjustment of complex manufacturing processes to consistently produce quality products. Used in a variety of continuous mass production industries, process control systems allow a few workers to control a large number of complex processes with a high degree of efficiency. Process control systems also improve safety, lower production costs, save energy, and decrease environmental impacts.

What Industries Use Process Control Systems?

Process control systems play an important role in most advanced manufacturing facilities, especially within industries focused on continuous mass production. Popular industries that rely heavily on process control include: power generation, oil and gas, chemical processing, pulp and paper, food and beverage, biotechnology, pharmaceuticals, semiconductors, plastics, petrochemicals, and water/wastewater.

What Types of Process Control Variables Are There?

Process variables can consist of anything that affects a physical or chemical process. The most common process variables fall into five major types: level, flow, temperature, analytical, and pressure. Analytical process variables are often called chemical variables, because they involve chemical properties like acidity. Other process variables include density, velocity, speed, stress, force, and weight.

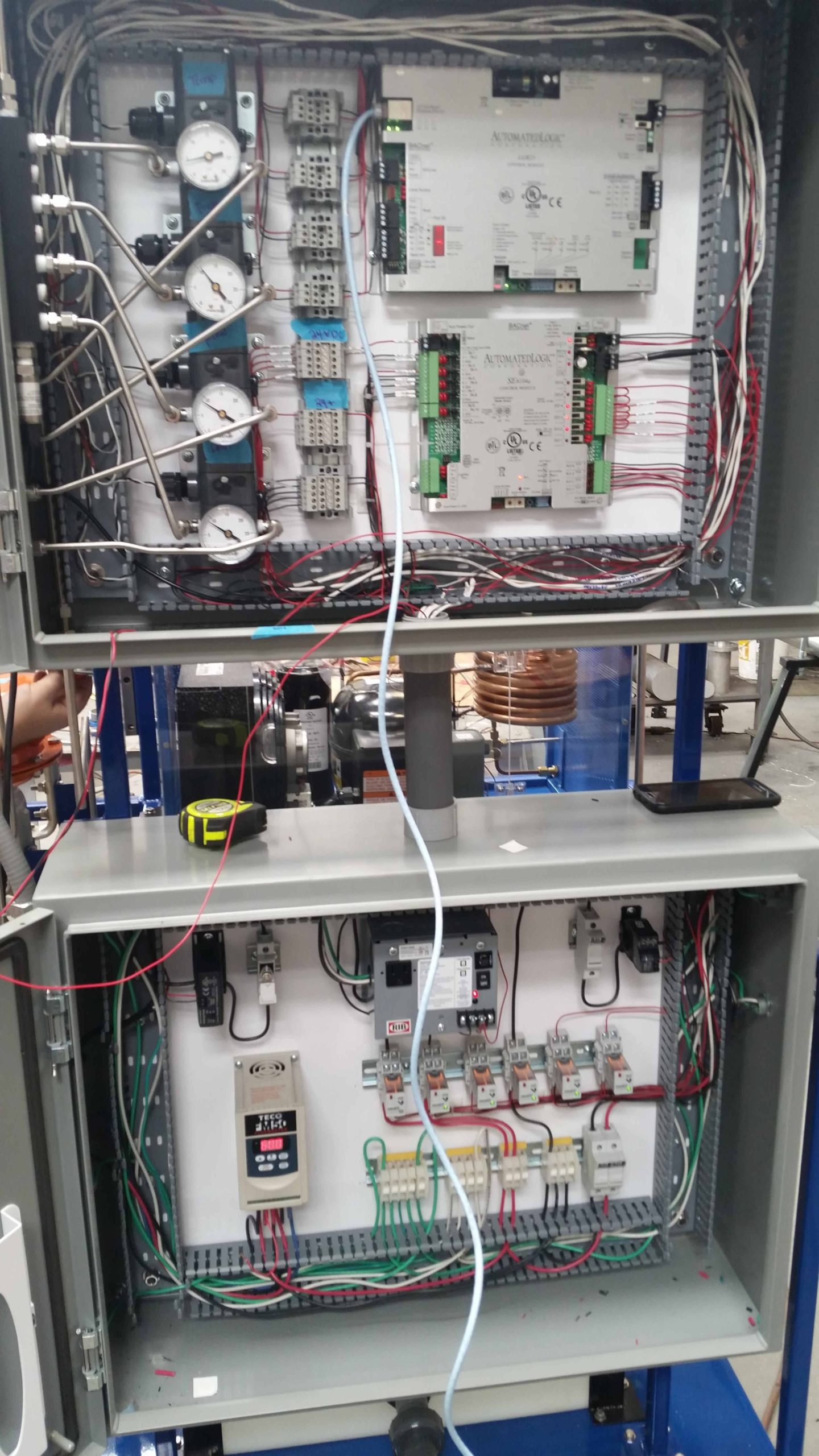

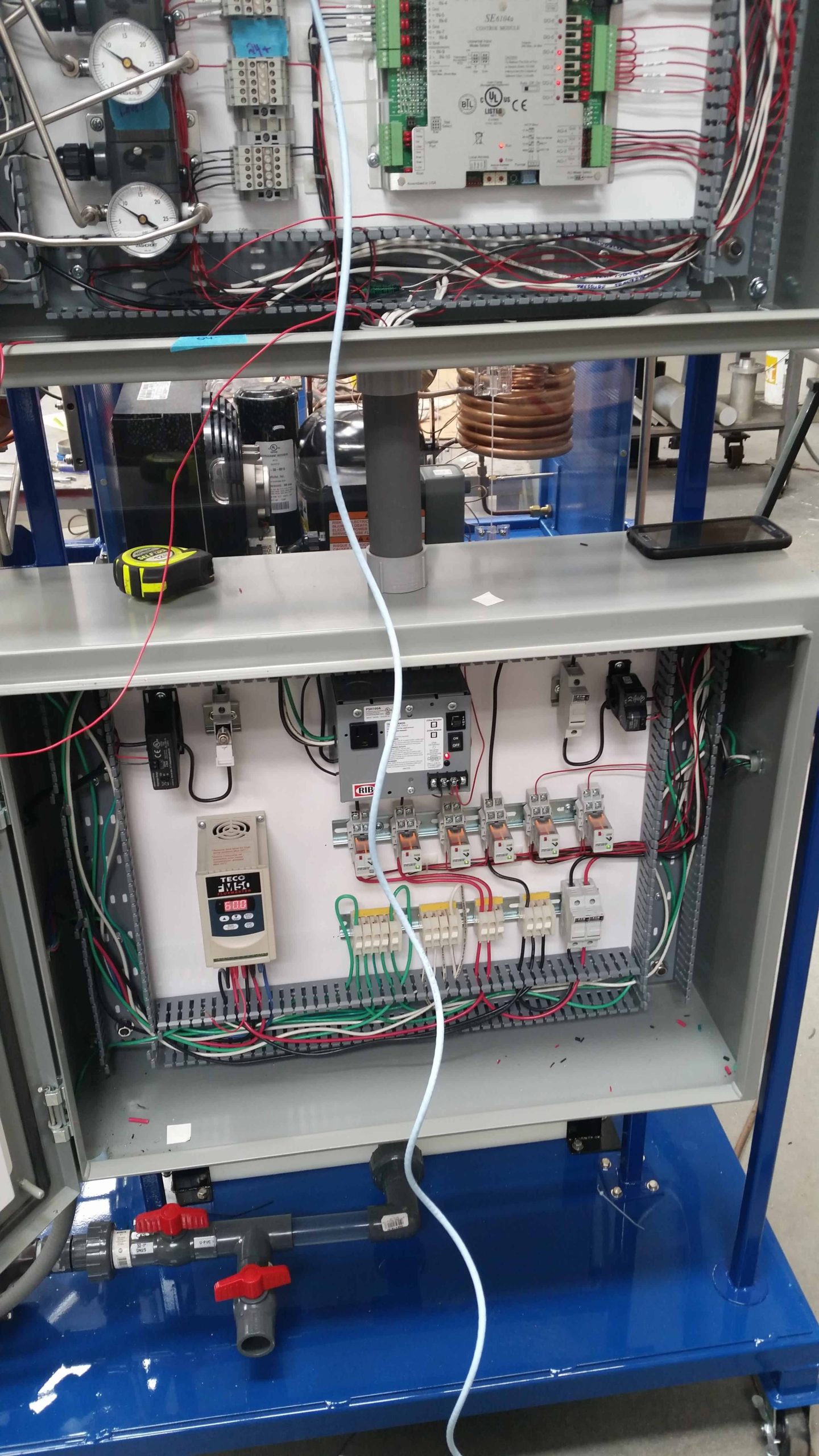

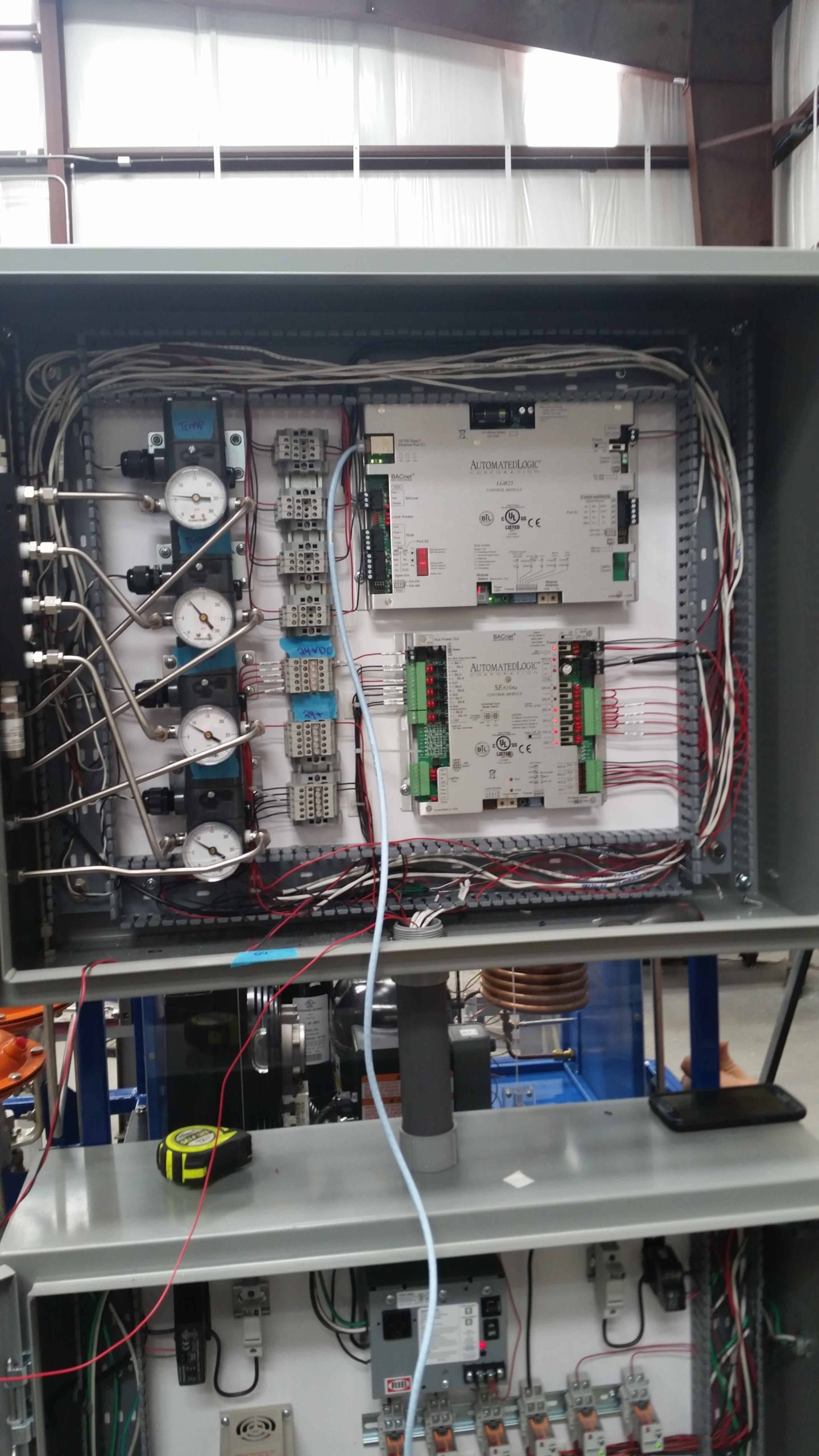

Bayport Technical's Instrumentation Process Trainer (120-IPT) is a hands-on training unit for process operators and instrument technicians. The unit replicates real-world operating equipment and consists of separate functions all integrated into a compact, effective unit in order to safely train personnel.

The Instrumentation Process trainer features a wide variety of industry-standard equipment, including: a magnetic centrifugal pump; an acrylic water column; a tank; a 3/4 HP motor; four (4) loops with control valves and transmitters for flow, level, pressure, and temperature; an HMI touchscreen and PLC; a motor control center; a pneumatic supply regulator and gauges; and standard operating manuals.