A common characteristic of most mechanical and chemical systems is the need to transfer heat from one fluid (liquid or gas) to another, and most systems use heat exchangers to accomplish this task. In a heat exchanger, the two fluids do not make direct contact. Instead, heat passes from the hotter fluid to the metal isolating the fluids and then to the cooler fluid.

Common applications of heat exchangers include heating, ventilation, and air conditioning (HVAC) systems; preheaters or coolers in fluid systems; radiators on internal combustion engines; and boilers, evaporators, and condensers used with fluids like oils, wastewater, hydrocarbons, biogases, etc. in industries such as oil and gas refining and power generation.

Although heat exchangers come in a wide variety of shapes, sizes, and designs, the most common and basic type is the shell and tube heat exchanger, which consists of a set of tubes inside a cylindrical shell. Fluids flow inside the tubes (tube-side fluids) and outside the tubes (shell-side fluids) and remain separated at the ends of the tubes by the tube sheets.

In a u-tube type heat exchanger, the tube bundle consists of continuous tubes bent into a “U” shape and secured to the shell by a tube sheet. The shape of the tubes directs fluid flow back and forth across the length of the heat exchanger, creating an inherent multi-pass design.

Since the bend side of the tubes if free floating in the shell, this design allows thermal expansion to occur without requiring expansion joints. This allows these types of heat exchangers to accommodate greater temperature differences than other designs.

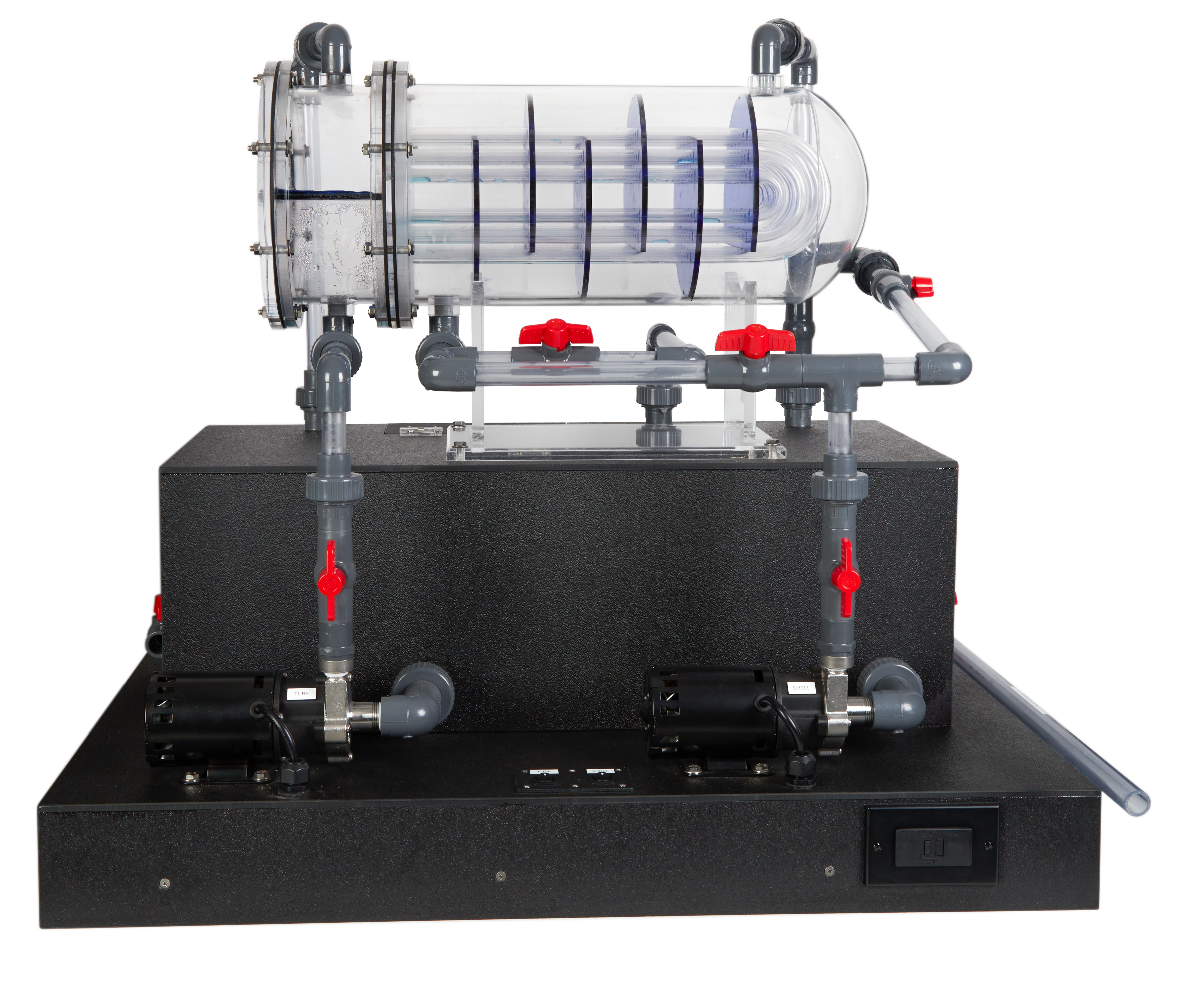

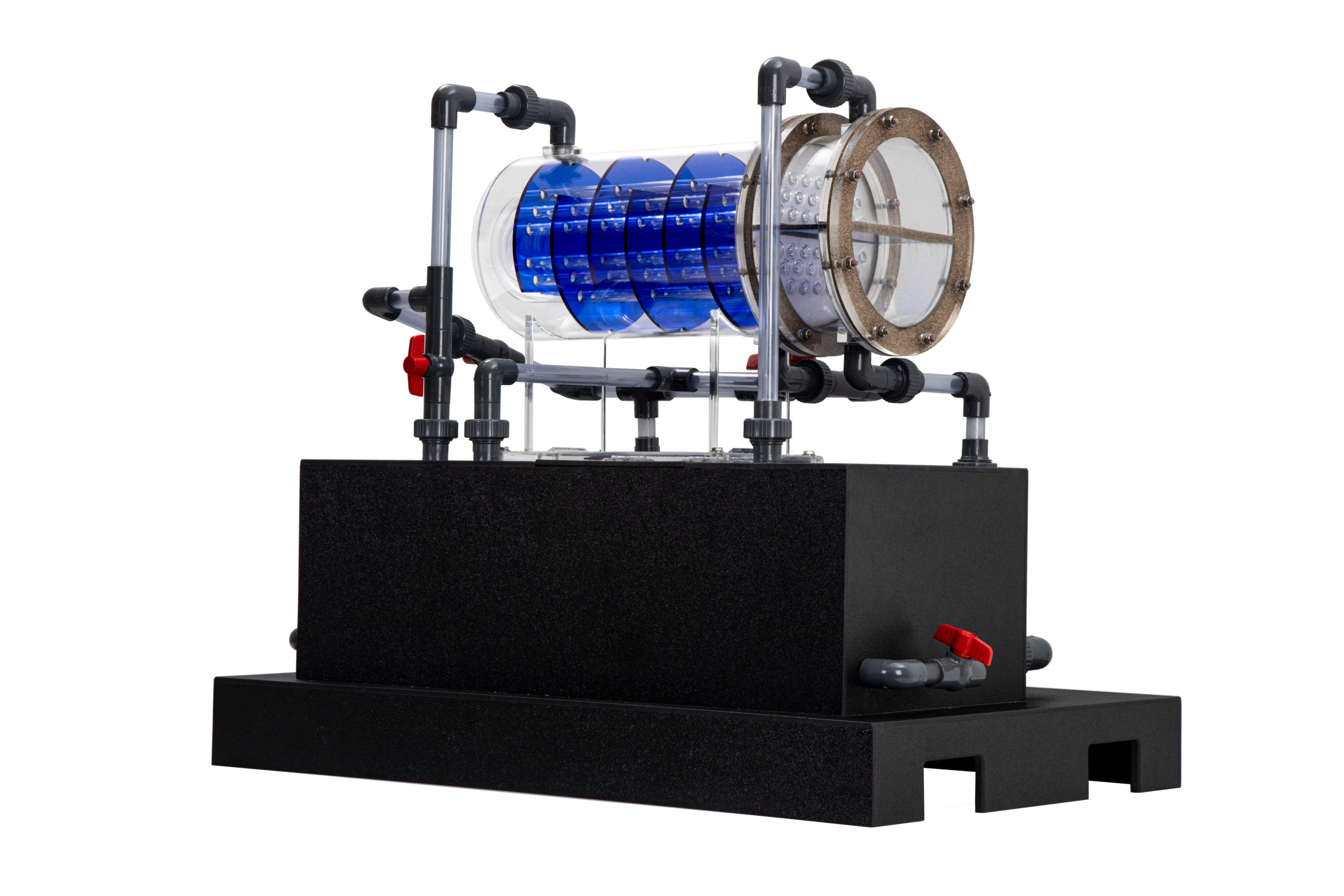

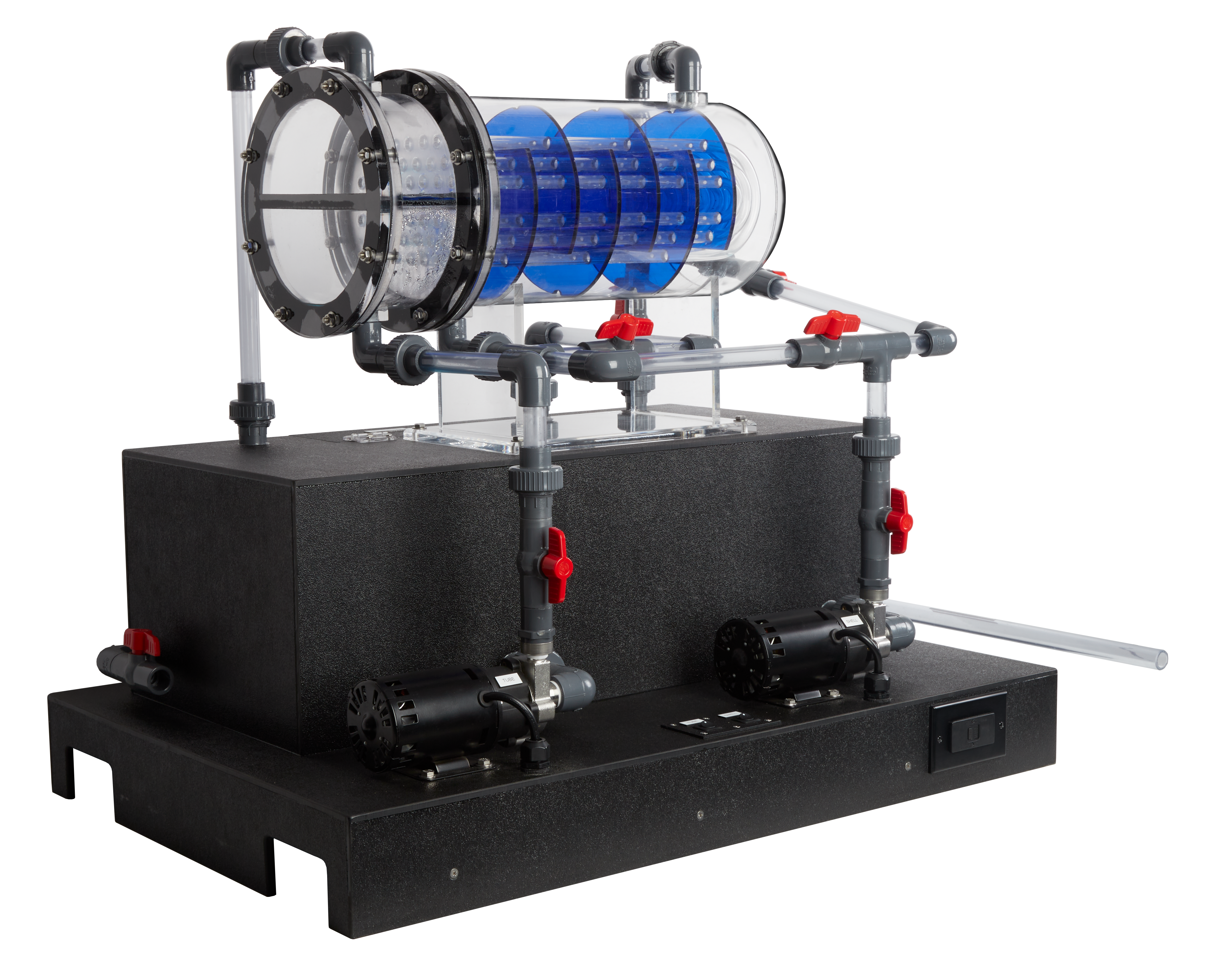

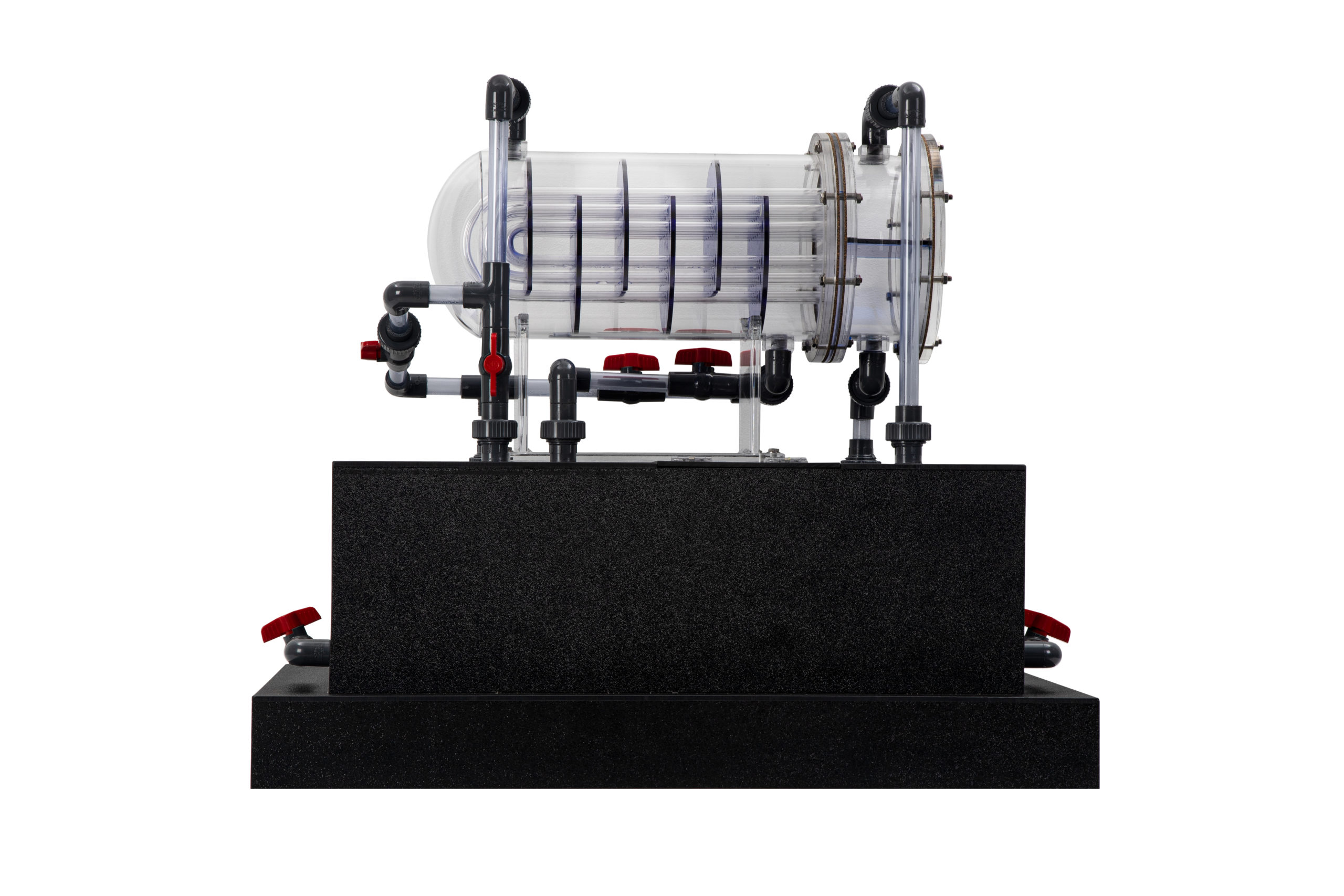

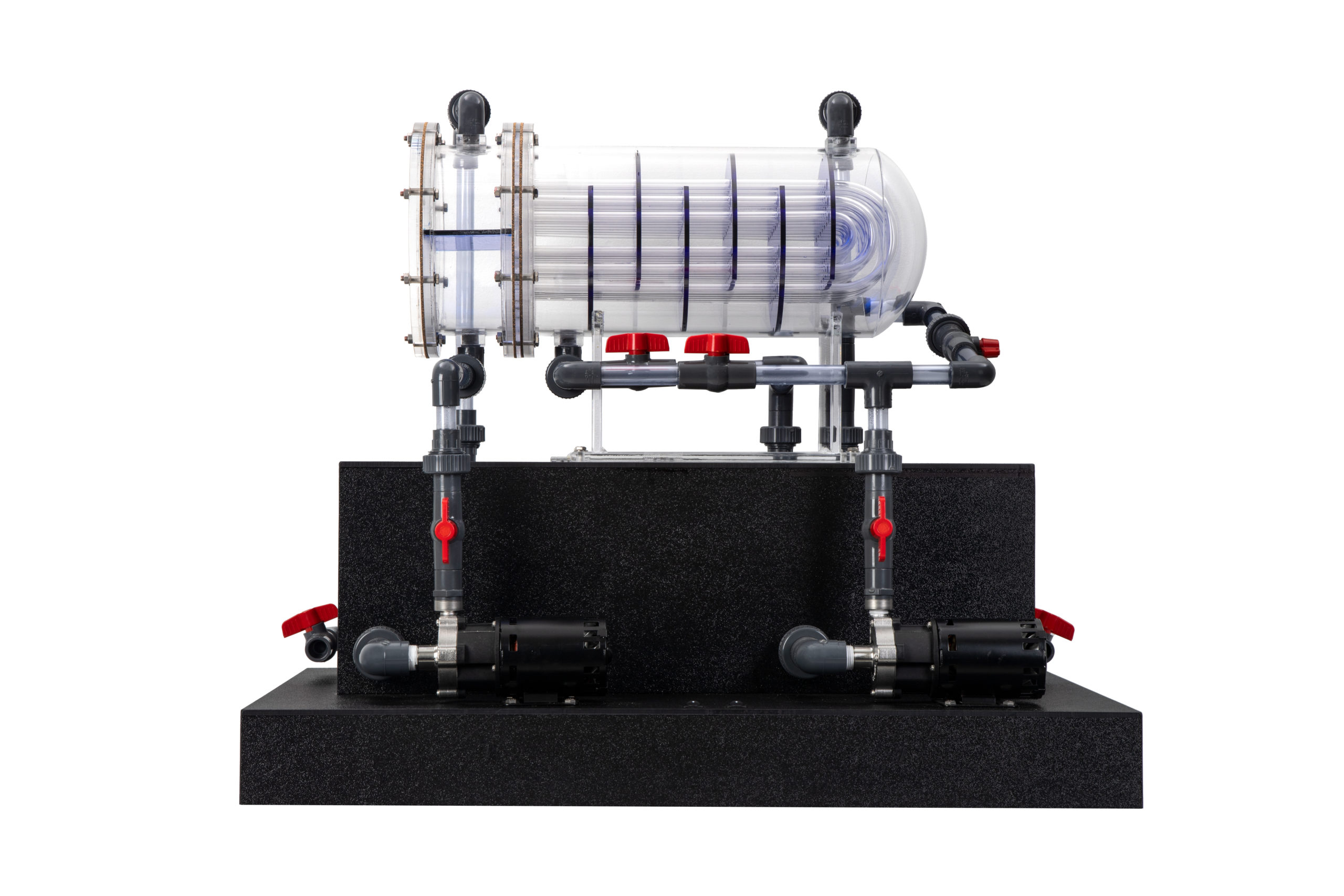

Bayport Technical's U-Tube Heat Exchanger Circulation Trainer with Backwash (110-HECT2) is a working model containing two circulation pumps and two supply tanks for demonstration. Different colored water streams are circulated from the shell side and through the tube side to simulate the working of a real heat exchanger.

In addition to following the flow of two different colored fluids through the acrylic heat exchanger shell and tubes, this transparent training tool allows the user to completely dismantle and reassemble the unit in the classroom to see what each component looks like and how the gaskets are positioned.

The U-Tube Heat Exchanger Circulation Trainer with Backwash also features the valves and manifold required to demonstrate backwash operations.